Cool It: The 5 Best Roofing Materials For Hot Climates

Which Roofing Material Has http://andresxybw290.lowescouponn.com/best-roofing-materials-to-top-off-your-house-in-2020 The Longest Lifespan?

Table of ContentsWe Are Metal Roofing ExpertsTypes Of Roofing To Choose From

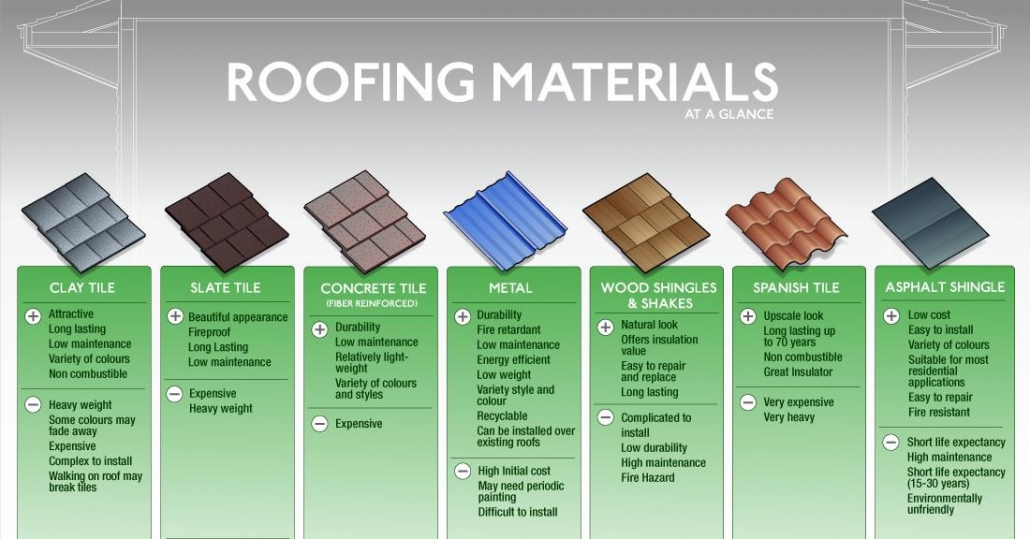

Metal roofing is still made in rolls, but many is stiff sheet roof with vertical-seam panels and modular press-formed panels that can be painted or coated with granules. The production processes enable a variety of look alternatives including the traditional metal roof design and roof made to appear like shingles, shakes and tiles. Why do property owners choose tiles? All types, clay, concrete and fiber cement, provide 50+ years of toughness Tiles withstand fire and insects The abundant aesthetics of tile increase curb appeal While not as differed as asphalt shingles, tiles are produced in a great series of colors, designs and textures Light-colored tile reflects sunshine, so decreases heat penetration and cooling requirements The tiles are recyclable Tiles look fantastic on Spanish/Mission, European, Mediterranean and some contemporary homes Tile is much heavier than many roof material and some types require extra framing support at a higher cost The expense of tile is greater than asphalt, metal and wood Tiles might break if walked on, so fixing chimneys and other roofing concerns is more difficult when the roofing is tile Some European structures have natural slate tile roofings that are centuries old; composite or vinyl slate tile is expected to last 40-60 years.

/cedar-dormer-585292078-3b8a5484157546118a5b9cd2c1288fa6.jpg) What Type Of Roofing Material Lasts The Longest?

What Type Of Roofing Material Lasts The Longest?

Roofs And Roofing Materials Comparisons

Roofs And Roofing Materials Comparisons

The size choices permit you to choose the best try to find your home's architecture. The benefits of slate are: The luxurious excellent appearances of genuine slate are unmatched Real slate is a "lifetime" roofing system for any building and enhances curb appeal and resale value Slate needs little maintenance Synthetic slate is lightweight yet strong This is a green roof product due to its resilience, the relatively low effect of manufacturing which it can be recycled and recycled Real slate is the heaviest roof material at up to 1,500 pounds per 100 square feet, so extra framing assistance (and extra cost) is necessary If a slate roofing system isn't effectively set up, wetness concerns will start rapidly Slate roofs ought to only be installed by professionals that focus on slate, so you should do your due diligence prior to hiring an installer Slate might break if walked on, so roofing and chimney repairs are more tough to make Tesla solar tile roofs constantly appear to be "increase", but are never ever actually offered to customers.

5 Types Of Roofs Considered The Best

5 Types Of Roofs Considered The Best

However, we are now in the second half of 2020, however that claim of producing 1,000 solar glass tiles a week hasn't emerged yet. More house owners would pick solar if the big PV panels weren't so noticeable and, frankly, awful. Tesla is trying to alter the video game with its solar tiles that look like standard tiles.

What Type Of Roof Last The Longest?

https://www.youtube.com/embed/DaZqiDpcvA4

That said, there are two kinds of solar roof tiles: BiPV solar tiles are made from glass over a photovoltaic (PV) substrate. They are wired to the Tesla Powerwall that incorporates the roof with your house's electrical system. Depending on the climate where you live, and whether you own a ranch or multistory home, Tesla will recommend protection with solar tiles of 35 to 70 percent.

10 Best Roofing Materials For Warmer Climates

Table of ContentsLongest Lasting Roofing MaterialsHow Long Does A Roof Last On Average? Solved!The 5 Most Durable Roofing Materials

Asphalt shingle is the most common roof material, though it is barely the longest enduring roofing system. It's price and ease of installation makes it incredibly popular. However, compared to stone, clay, or metal, asphalt shingle has a reasonably short life expectancy. The majority of asphalt shingle needs to be changed every 20-30 years.

How Long Does A Roof Last On Average? Solved!

How Long Does A Roof Last On Average? Solved!

Because it is a manufactured product, its resilience varies considerably by manufacturer and item. Asphalt shingle utilizes tar adhesive to bond the overlapping shingles together. When installed in the right conditions, this adhesive bond is very strong and withstands leaking. The life-span of an asphalt shingle roof can be extended with appropriate care.

Likewise, an asphalt shingle roofing must be checked after a severe storm or other severe weather and repaired as essential. Routine repair and maintenance can greatly extend the life expectancy of an asphalt shingle roofing. Wood is a natural product and is susceptible to bugs, bugs, https://felixhbmn900.creatorlink.net/how-long-can-you-expect-your-roof-o and rot. Shake tends to last longer than regular wood shingles, however any wooden roof product will have the quickest life-span among common roof products.

The benefits of wooden roof are both aesthetic and useful. Lots of house owners prefer the appearance of wood shingles or shake. Likewise, wood shingles are fairly basic and inexpensive to install. Lots of house owners have actually never even heard of underlayment. However underlayment is really considerable to the durability of your roofing system. Underlayment is a product laid straight on the roof and beneath the shingles.

What Type Of Roof Lasts The Longest?

Underlayment is water resistant, not waterproof, however it acts as a good emergency situation barrier when it comes to damage to the shingles above it. In the case of asphalt shingles, it prevents shingles from bonding directly to the plywood roof, making it much easier to get rid of when the time pertains to change the roofing.

A low quality of underlayment can restrict the longevity of otherwise long-term roofing materials. However when you look at historical buildings that used slate, clay, and concrete tiles, none of them utilized underlayment. Yet they still function today. This simply shows that underlayment is very important to think about, however not essential in every circumstance.

Just going for the longest long lasting product may not constantly be the best choice. At Eagle Watch Roof, we can aid with your roofing system repair or your total roofing system replacement. Our specialists will enjoy to discuss your options and set up the very best roofing system for your house.

Will Your Next Asphalt Roof Last A Lifetime?

Will Your Next Asphalt Roof Last A Lifetime?

This detailed guide to roofing materials is all the research study you'll need to examine the top choices for residential re-roofing and new building jobs in 2020 In this guide we'll cover the following most common roof choices: asphalt shingles, wood shingles and shakes, metal roof, concrete, clay, and fiber-cement tiles, natural and synthetic slate, and the much-hyped Tesla solar tiles that are not yet extensively available.

Roofing Buying Guide

More than 75 percent of all single-family homes in the US are roofed with asphalt shingles, though that number is slowly shrinking thanks to the more energy-efficient and long lasting metal roof. Asphalt (structure) shingles dominate the marketplace due to the fact that they are affordable, use a range of appealing alternatives, and do a great job securing homes from the nature's components.

The Pros & Cons Of Different Roofing Materials

The Pros & Cons Of Different Roofing Materials

Shingles made with fiberglass are light-weight and resist tearing. Organic asphalt shingles start with paper, often recycled, that is saturated in asphalt and covered with granules. The shingles are heavier and more difficult to work with than fiberglass, however they normally offer much better stability in high winds. Although you can still see them on many roofing systems, organic shingles have actually been mostly phased out or discontinued over the course of last years.

https://www.youtube.com/embed/OrzKWZ1Mw-o

Fiberglass shingles provide excellent fire defense Look excellent on the majority of any design home Shingles are often the most budget friendly roofing choice, especially in good/better ranges The very best asphalt shingles are a 30-year roofing option set up on homes located in moderate environments The most affordable 3-tab shingles are an inexpensive method to dress up a home prior to selling Broad choice of colors and designs consisting of affordable three-tab and architectural shingles that simulate shakes and slate Do It Yourself asphalt shingle setup is possible for those with good skills, experience and equipment No assistance beyond basic roofing system sheathing is required for shingles are ranked for 60-70 MPH wind uplift, while requirement are ranked for 110 MPH winds; are ranked for 130 MPH such as the ones produced by GAF must be utilized for heavily-wooded areas and areas where big hail is possible Some shingle repair work are easy and economical The lifetime expense of shingles is higher than metal, tile or slate, due to the fact that structure shingles must be replaced more frequently Less expensive asphalt shingles last as low as 10-15 years in hot, bright environments Fast temperature level changes can cause asphalt shingles to split An inadequately vented attic will trap heat and considerably shorten asphalt shingle life expectancy by cupping or breaking them While the asphalt shingle market boasts that its items can be recycled for paving, couple of recycling facilities take asphalt shingles, and they are among the least environment-friendly roofing choices After a 2nd layer of shingles requires replacing, all layers need to be detached the roofing, producing additional cost and a lot of possible garbage dump waste Mold or algae can be a problem on shingles in dubious locations, unless treated with anti-algae/anti-stain treatments Organic/felt shingles are heavy; getting them to the roofing system in packages can be an obstacle Wood provides a natural dosage of appeal to any roofing.

Liquid Applied Roofing Membranes

Table of ContentsElastomeric Roof CoatingsRoof Sealants & Coating At Ace HardwareFrequently Asked QuestionsElastomeric Roof CoatingsWhy Armor Roof Coatings Are The Best

This is also to prevent leaks, slow down mould development and buildup of moisture that ruins roof membranes slowly. Waterproofing is crucial to the life of the roofing system and the entire house structure. With roof finish, the roofing becomes impermeable to water, no matter how strong the rain could be.

Consider An http://rylanlfou751.image-perth.org/how-much-does-roof-coating-cost-per-square-foot Elastomeric Roof Coating

Consider An http://rylanlfou751.image-perth.org/how-much-does-roof-coating-cost-per-square-foot Elastomeric Roof Coating

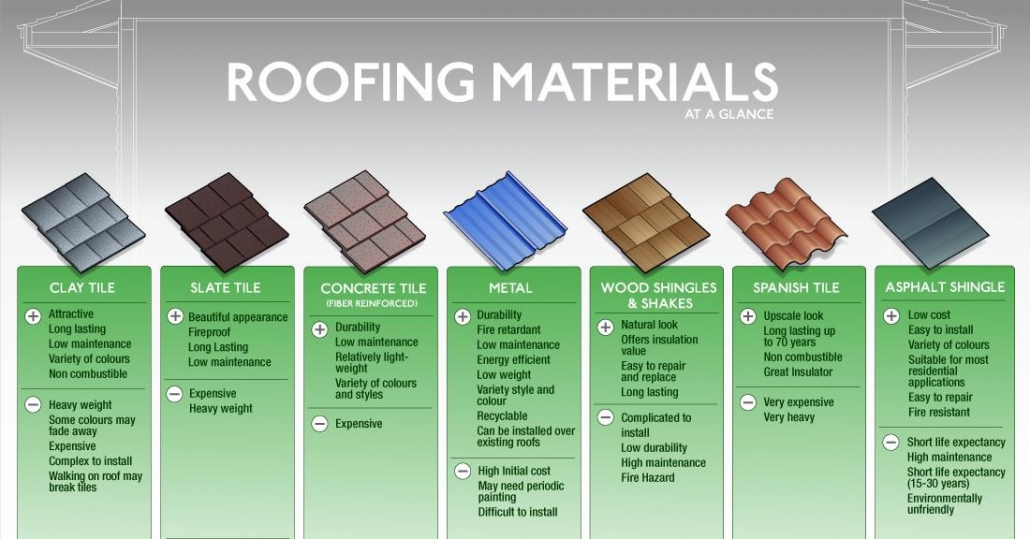

Different roofing materials require various roof coverings. A roofing coating is thicker than paint. It has elastomeric properties that enhance the roofing system's surface area, producing a thick film that seals cracks in between flashings, gutters, and tiles. Roofs without coats could easily harm roof membranes due to leakages. Metal roofs and other types such as EPDM, bitumen, tar, or spray polyurethane are best examples of roofs needed with a roofing system finishing.

Risks include UV rays, snow, strong wind, and water. The roofing system ends up being an impressive piece of work when upon installation roofing system finish is applied. Entirely, the roof preserves its stability because of the coat's protective homes. Roofing system coverings are made to come up with a different formula that applies to each type of roofing material.

Roofing 101: Roof Coatings

Acrylic coatthe homes of acrylic finish include moisture resistance, weather resistance, versatility, and oxygen permeability. Roofing system finish made from acrylic is elastomeric and has outstanding reflective homes against the damaging ultraviolet rays. Acrylic roofing finish is recommended for sloped roofings, and it is much less expensive compared to other types of finishes. With such activity, the surface area is exposed to human traffic, thereby, enhancing the roofing system with a polyurethane finishing will safeguard the surface from abrasive damage. Even with the most difficult roofing system covering around, it diminishes in time. However including the number of years on the lifespan of any type of roofing, roof finishes are crucial to the roofing system's longevity.

Problems on membranes and insulation blamed to leakages, provide the ramification that the roofing has actually not been correctly coated. Roofing professionals dealing with applying roof coat. An inadequate roof finish can not be spotted quickly by the naked eye. Nevertheless, a professional roofers might understand the problem in your roofing system. If the roof coating fades off faster than anticipated, call a reputable roofing professional to fix any prospective damage instantly.

The ideal time it can last is 10 years. Envision that the additional years for your roofing's lifespan is a matter of making the right decision and understanding how to improve the stability of the roofing system. However, the performance of roof coverings depends on where you live or on what weather conditions you are experiencing.

Roofing 101: Roof Coatings

Are you headed for a roofing system repair? Do you want to save on energy? Or is your area vulnerable to weather dangers? To understand the roof coating with the finest home that applies to your building or home, employ an expert roofing specialist and let him check the stability of your roofing.

An elastomeric roofing system finish is an elastic covering used to a variety of roofing types to protect and seal the underlying roofing material, assistance stop and avoid leaks, and limitation future weathering. They are developed to move with your roof and be more forgiving rather than stay rigid, a quality that makes them particularly durable.

The term elastomeric comes from the covering's flexible quality to stretch and move. Elastomeric roofing finishes can be utilized on numerous industrial and commercial roofing types such as metal roofing systems, concrete roofings, bitumen, modified bitumen or BUR roofings, EPDM roofs, or as a sealant over brand-new PUF roofings. The very best value from a roofing finishing comes when you use it at the very first sign of aging.

Elastomeric Roof Coatings

Too frequently, it costs you a new roofing system, at three or four times the cost of a roofing system covering, which might have been prevented by paying attention to early signals. After examining all of the numerous elastomeric roofing coverings on the marketplace, how do you pick the best quality and worth roof covering for your needs? Comprehending the whole roof repair procedure will assist you to select which elastomeric roofing system finishing best suits your needs.

It pays to compare all the physical residential or commercial properties because it only takes a weak point of one to result in failure. Some roof conditions, such as rust or leakages at seams or flashings, might make it necessary to use specific items in addition to a covering. If you believe your roof may require more than simply a covering, we recommend researching roofing system repair alternatives.

![]() Why Does It Matter If My Roof Coating Is Elastomeric?

Why Does It Matter If My Roof Coating Is Elastomeric?

To find out more about the complete roofing repair procedure, read our full guide and see the video listed below: When determining the best elastomeric roofing finish to utilize on your roofing, there are numerous physical homes that need to be taken into consideration. Every roofing is various in terms of building, place, weather, sunlight, and so on.

White Elastomeric Roof Coating

The very best roofing finishings ought to carry out well for you on every count. Here are the residential or commercial properties to assess: Elasticity is the ability of a product to stretch. The ability to stretch and also recuperate methods that a roofing finish can move with the expansion and contraction of the roofing as the temperature changes without splitting.

https://www.youtube.com/embed/MrQEQcrjwFI

Bubblegum for example has incredible elasticity. But since it has no recovery, stretching it only makes it thinner and eventually a mess. The greater the flexibility, the more most likely the product will endure your requirements and changes in the roofing structure. When you pair this with recovery you get an item which can keep carrying out for your requirements.

Quick Reference: Types Of Roof Coatings

Table of ContentsElastomeric Acrylic Coatings Application HandbookMyths, Facts, And The Truth About Silicone And ElastomericHow Do You Apply Elastomeric Roof CoatingButyl Elastomeric Roof Coating Explained

They require more material to accomplish the wanted dry film density, making them less cost-efficient than other elastomeric coverings. They can likewise be challenging to spray and hard on application equipment. Silicone roofing system finishings are the favored choice when it comes to UV protection and resistance to ponding water. They erode much slower than other coverings without becoming brittle or difficult.

This suggests less product is required to accomplish the required dry film thickness. Silicone finishes are created by including solvents and a driver to a silicone base. Offered in white, gray, or tan, silicone can be set up on a variety of roofing system types including metal, customized bitumen, single-ply, EPDM, built-up roofings, and spray polyurethane foam.

Silicones bring in dirt rather easily. This means the system will gradually lose reflectivity over time if not cleaned periodically. They are likewise extremely slippery when wetness exists. Resistance to tearing is another fundamental weak point. If pedestrian traffic is expected on the roof, we extremely recommend including roofing granules into the system.

When it concerns strength, sturdiness, and adhesion, urethane roofing system coverings are 2nd to none. Compared to other finishes, they are more impact-resistant and are much better matched to handle https://laneefyt265.skyrock.com/3336129346-Liquid-Applied-Roof-System.html pedestrian traffic. They are also strong enough to sustain the natural growth and contraction (thermal motion) of roofing system structures and the unfavorable impacts of ponding water.

How To Choose The Best Elastomeric Roof Coating

Aliphatics are usually used as leading coat, as they are more UV stable, resistant to dirt pick-up, and have exceptional color retention. Aromatics are more economical however not quite as UV steady. They are primarily used as a structure covering in the majority of roof restoration systems. Both types can be spray or roll-applied, with most system specifications needing several coats at a rate of 1.5 gallons per 100 square feet.

Acrylic Or Silicone Roof Coatings For Your Commercial Roof?

Acrylic Or Silicone Roof Coatings For Your Commercial Roof?

It's also worth mentioning that urethanes are a moisture-cure coating, implying they are constantly curingeven in the pail. Every business roofing system is different. That's why it's important to evaluate certain physical properties of a finish to guarantee its suitability in a particular roof environment. Each home listed below, in addition to other technical information, can be found in the producer's product data sheets.

Many elastomeric finishes usually measure anywhere in between 250-900%. The greater the elongation worth, the more suited a covering is to sustain the typical expansion and contraction of a roof structure without breaking, thinning, or peeling off. Tensile strength is the amount of pressure a material can withstand prior to it breaks.

Elongation and tensile strength are closely associated but in an inverted instructions. As one increases, the other reductions. The best business roof finishing solutions stabilize the 2 residential or commercial properties to supply a strong, resilient membrane that can adequately extend and move with roofing system surfaces. Permeability, or perm rating, is the state or quality of a material or membrane that triggers it to allow liquids or gases to travel through it.

Elastomeric Roof Coating

How-to: Apply Cool Roof Coating

How-to: Apply Cool Roof Coating

For example, acrylics have a high perm rating, meaning they are really breathable. Silicones, on the other hand, have a lower perm ranking implying they have superior resistance to wetness transmission. It is essential to note that greater permeability does not correspond to inferior weather resistance. Reflectivity determines the amount in which a product can reflect light.

Unlike traditional, dark-colored roofing materials, white roofing finishing systems show 80-90% of the sun's energy back into the atmospheresignificantly minimizing the danger of heat gain throughout the roofing system structure. Emissivity refers to a material's capability to launch absorbed heat. This home is normally represented as a decimal between 0 and 1, with 0.65 being considered perfect for an elastomeric roofing coating.

Solids by volume is the measure of how much solid product will stay after a compound has dried. Understanding this residential or commercial property is critical in order to effectively attain the required dry movie thickness specified for particular finishing systems. While it has no bearing on the performance of a coating, this particular home is certainly worth some factor to consider.

For a total summary of the physical homes for American WeatherStar items, click on this link to download our full roofing finishing contrast chart. Ultimately, the performance of a commercial roofing system finish depends upon a variety of factors. Each chemistry has its own unique set of strengths and weaknesses. Things like roofing type, age, environmental issues, aesthetic appeals, and more need to be taken into consideration before selecting a suitable, long-term option.

How Much Does It Cost To Coat Or Seal A Roof?

In the business roofing worldand especially in our restoration/revitalization specialized areawe utilize a lot of technical terminology that we recognize our customers might not be familiar with. This understandably leads to lots of concerns, and it's our objective to educate the structure owners and managers we deal with as we bring new life to old, tired roofings.

Elastomeric Roof Coating Contractors Battle Creek

Elastomeric Roof Coating Contractors Battle Creek

While there tends to be some dispute in the industry as to what specific roof finishes and products qualify as "elastomeric," the definition of this term is rather basic. It describes compounds that are elastomers, or that have flexible properties. Simply put, elastomeric products stretch and can go back to their initial measurements after doing sothink of an elastic band, and you'll have the ideal concept.

They are very protective versus extreme weather condition, UV light from the sun, and even foot traffic on your roofing system. The type of elastomeric covering that's most suitable for your business structure's roof will depend on what materials it was initially made from. Professional roof specialists like us will work with you to assist you choose the best-performing coating for your special roofing.

https://www.youtube.com/embed/ubKYOfLtEhI

Elastomeric roofing coverings are created to assist stop leaks in aging roof made from a range of materials, like metal, layered asphalt, single-ply membranes, and more. When correctly applied by professionals, these restorative coatings can seal problematic seams and produce a 100% leak-proof barrier across the surface area of your roofing.

Best Roofing Buying Guide

Table of ContentsThe Top 7 Most Durable, Long Lasting Roof MaterialsDifferent Types Of Roofing Materials AvailableMost Popular Roofing Materials

It's not all about the charm, after all. It is likewise unbeatable in the durability department. Now that you have actually discovered the most long-lasting roof materials, let now talk about things that can assist them reach their fullest capacity. Longevity can differ. This is since of the several elements that impact roof materials' capability to prolong their life service.

There are roof materials that are proven to carry out well even amidst the harshest weather. To know whether or not a roof item is premium or not, you need skilled viewpoints from relied on roof specialists. Depending on where you are situated, there are roof systems that can prosper better in particular climates or climate condition.

How Long Does A Roof Last - Updated Guide For 2020

How Long Does A Roof Last - Updated Guide For 2020

For example, even if you http://claytonzuhm803.iamarrows.com/2020-buyer-s-guide-long-lasting-roofing-materials have a lasting roofing material, consistent UV ray exposure may accelerate its deterioration. Natural occurrences run out out of our control as people but we can constantly pick to secure our homes with the assistance of professional maintenance treatments. We frequently state this and we'll restate it once again. Some house owners downplay the function of maintenance due to the fact that they seem like their roof can survive on its own. False. You require to roof leak repair help your roofing reach its optimum level by making certain that you address any potential or existing concern the minute you discover out about it. There are heaps of roofing products that are available today.

Best Roofing Buying Guide

Thanks to innovation, we'll constantly have the ability to find something that would fit our own requirements, style choices, and even our long-term top priorities. Constantly remember, longevity is incredibly essential. But there are other factors to consist of in the formula such as expense, negative qualities, and so on. Would like to know what roof products would work for you?The group is constantly available for an assessment.

Thus, we encourage you to talk to our roof professionals to learn what roofing products would fit your needs. Call us at and receive a.

The life-span of your roofing system will depend on a myriad of factors, such as its design, environmental conditions, quality of installation, and direct exposure to the aspects. Similarly, taking appropriate care of your roofing with routine evaluations and prompt repair work when needed can assist you get the most out of your roofing system.

How roof repair companies Long Can You Expect Your Roof Or Fridge To Last

Different Types Of Roofs That Increase Home Value

Different Types Of Roofs That Increase Home Value

If you are looking to replace your roof or set up a roofing for a new building and construction project, it is very important to consider the different life expectancies of roof products when making your decision.: 15 to 20 years: 10 to thirty years: 50+ years: 50+ years: 50+ years: 25+ years -Up roofings: 25-30 years -Ply: 30+ years The average roof will last around 20 years, though correctly maintained roofings can last far longer than their guarantees suggest.

In addition to selecting the right type, it is essential to pick a brand of roofing product that is known for being top quality. For example, while wood shingles in general may be estimated to last from 15 to twenty years, opting for low-grade shingles to save a couple of bucks will likely shave a couple of years off of its life.

https://www.youtube.com/embed/lIe98EebhnM

It is similarly crucial to ensure your roofing system is set up by a trustworthy roofing company that complies with all building and security codes.: Incorrect setup can and will void your maker's service warranty. At Lyons Roofing, our Phoenix and Tucson roofing contractors have actually gone far for ourselves due to our unwavering dedication to quality both in workmanship and in customer care.

Liquid-Applied Waterproofing Roofing Products

Table of ContentsHow Long Do Roof Coatings Last?The Benefits Of Elastomeric Roof CoatingWhy Does It Matter If My Roof Coating Is Elastomeric?Roof Coating Contractor

They require more product to achieve the preferred dry movie density, making them less affordable than other elastomeric coverings. They can likewise be challenging to spray and difficult on application devices. Silicone roofing finishings are the preferred option when it concerns UV security and resistance to ponding water. They wear down much slower tile roofing repair than other coatings without ending up being brittle or difficult.

This implies less product is required to attain the required dry movie density. Silicone coverings are created by adding solvents and a driver to a silicone base. Available in white, gray, or tan, silicone can be installed on a range of roofing system types consisting of metal, modified bitumen, single-ply, EPDM, built-up roofing systems, and spray polyurethane foam.

Silicones attract dirt rather easily. This indicates the system will gradually lose reflectivity over time if not cleaned up periodically. They are likewise incredibly slippery when wetness is present. Resistance to tearing is another intrinsic weakness. If pedestrian traffic is expected on the roof, we extremely suggest integrating roofing granules into the system.

When it pertains to strength, durability, and adhesion, urethane roofing coverings are second to none. Compared to other finishes, they are more impact-resistant and are much better fit to deal with pedestrian traffic. They are also strong enough to endure the natural expansion and contraction (thermal motion) of roofing system structures and the negative results of ponding water.

5 Reasons Why Elastomeric Paint Is The Best Exterior Paint

Aliphatics are usually used as top coat, as they are more UV stable, resistant to dirt pick-up, and have exceptional color retention. Aromatics are cheaper but not quite as UV steady. They are primarily utilized as a foundation covering in the majority of roof restoration systems. Both types can be spray or roll-applied, with many system specs needing several coats at a rate of 1.5 gallons per 100 square feet.

Kool Seal Elastomeric Roof Coating

Kool Seal Elastomeric Roof Coating

It's likewise worth mentioning that urethanes are a moisture-cure finishing, suggesting they are continuously curingeven in the pail. Every industrial roofing is different. That's why it is essential to evaluate particular physical residential or commercial properties of a coating to guarantee its viability in a specific roofing environment. Each residential or commercial property noted below, along with other technical data, can be discovered in the manufacturer's product data sheets.

Most elastomeric coverings generally determine anywhere in between 250-900%. The greater the elongation worth, the more matched a finishing is to sustain the typical growth and contraction of a roofing system structure without breaking, thinning, or removing. Tensile strength is the quantity of pressure a product can hold up against prior to it breaks.

Elongation and tensile strength are carefully related however in an inverse instructions. As one boosts, the other decreases. The best industrial roofing system covering solutions stabilize the 2 properties to offer a strong, durable membrane that can sufficiently extend and move with roofing surfaces. Permeability, how much to repair flashing on roof or perm ranking, is the state or quality of a product or membrane that triggers it to allow liquids or gases to go through it.

How Long Does A Flat Modified Bitumen Roof Last?

How Long Do Roof Coatings Last?

How Long Do Roof Coatings Last?

For example, acrylics have a high perm ranking, suggesting they are extremely breathable. Silicones, on the other hand, have a lower perm ranking indicating they have exceptional resistance to moisture transmission. It is necessary to keep in mind that higher permeability does not equate to inferior weather resistance. Reflectivity measures the amount in which a product can show light.

Unlike traditional, dark-colored roofing materials, white roofing system finish systems reflect 80-90% of the sun's energy back into the atmospheresignificantly lowering the danger of heat gain throughout the roofing system structure. Emissivity describes a material's capability to launch taken in heat. This residential or commercial property is typically represented as a decimal between 0 and 1, with 0.65 being considered ideal for an elastomeric roofing system finish.

Solids by volume is the procedure of how much strong material will stay after a substance has actually dried. Comprehending this residential or commercial property is important in order to effectively achieve the needed dry movie density specified for particular finish systems. While it has no bearing on the performance of a finishing, this particular home is certainly worth some consideration.

For a complete overview of the physical properties for American WeatherStar items, click on this link to download our complete roofing finish comparison chart. Ultimately, the performance of a business roof finish depends on a variety of aspects. Each chemistry has its own special set of strengths and weaknesses. Things like roof type, age, environmental issues, aesthetics, and more need to be taken into consideration before selecting an ideal, long-lasting service.

How To Choose The Best Elastomeric Roof Coating

In the business roof worldand https://www.evernote.com/shard/s414/sh/170329cf-9aeb-6876-20d8-c11cc99096a5/bd2ab16871230bdb79c2470dc8b1ce84 particularly in our restoration/revitalization specialty areawe use a lot of technical terminology that we understand our consumers might not recognize with. This understandably causes a lot of concerns, and it's our objective to educate the structure owners and supervisors we deal with as we bring new life to old, tired roofings.

![]() Why Armor Roof Coatings Are The Best

Why Armor Roof Coatings Are The Best

While there tends to be some argument in the market regarding what specific roofing finishings and products certify as "elastomeric," the meaning of this term is rather basic. It refers to substances that are elastomers, or that have elastic homes. Simply put, elastomeric materials stretch and can go back to their original measurements after doing sothink of an elastic band, and you'll have the best idea.

They are exceptionally protective against extreme weather condition, UV light from the sun, and even foot traffic on your roof. The kind of elastomeric finishing that's most appropriate for your business building's roofing system will depend on what materials it was initially made from. Professional roof professionals like us will work with you to assist you choose the best-performing finish for your special roof.

https://www.youtube.com/embed/eRVMXcfwRY0

Elastomeric roof coatings are designed to help stop leakages in aging roof systems made from a range of products, like metal, layered asphalt, single-ply membranes, and more. When properly used by specialists, these corrective coatings can seal troublesome seams and develop a 100% leak-proof barrier throughout the surface of your roofing.

What Type Of Roof Last The Longest?

Table of ContentsMost Popular Roofing MaterialsWhat Type Of Roofing Materials Last The LongestWhich Roofing Materials Last The Longest?

Asphalt shingle is the most typical roof product, though it is barely the longest lasting roofing system. It's price and ease of setup makes it exceptionally popular. However, compared to stone, clay, or metal, asphalt shingle has a fairly short lifespan. Many asphalt shingle needs to be replaced every 20-30 years.

10 Best Roofing Materials For Warmer Climates

10 Best Roofing Materials For Warmer Climates

Due to the fact that it is a produced product, its toughness varies considerably by producer and product. Asphalt shingle uses tar adhesive to bond the overlapping shingles together. When installed in the right conditions, this adhesive bond is extremely strong and resists dripping. The lifespan of an asphalt shingle roofing system can be extended with correct care.

Likewise, an asphalt shingle roofing system must be inspected after a serious storm or other severe weather and fixed as required. Regular repair and maintenance can considerably extend the lifespan of an asphalt shingle roofing system. Wood is a natural product and is susceptible to bugs, insects, and rot. Shake roof gutter repair tends to last longer than regular wood shingles, but any wooden roof product will have the quickest lifespan amongst typical roof products.

The advantages of wood roofing are both visual and practical. Lots of property owners prefer the look of wood shingles or shake. Also, wood shingles are reasonably simple and cheap to set up. Numerous property owners have actually never ever even become aware of underlayment. However underlayment is very substantial to the longevity of your roofing system. Underlayment is a product laid directly on the roof and beneath the shingles.

What Roofing Material Is The Best?

Underlayment is water resistant, not waterproof, however it acts as a great emergency situation barrier when it comes to damage to the shingles above it. When it comes to asphalt shingles, it prevents shingles from bonding directly to the plywood roof, making it simpler to eliminate when the time comes to replace the roof.

A low quality of underlayment can limit the durability of otherwise long-term roofing materials. But when you take a look at historical buildings that used https://griffinhhel338.hatenablog.com/entry/2020/10/09/140738 slate, clay, and concrete tiles, none utilized underlayment. Yet they still operate today. This simply shows that underlayment is crucial to consider, but not required in every circumstance.

Just choosing the longest enduring product may not constantly be the best option. At Eagle Watch Roof, we can help with your roofing repair work or your complete roof replacement. Our professionals will enjoy to discuss your choices and install the best roofing system for your home.

This comprehensive guide to roofing products is all the research study you'll require to assess the top options for property re-roofing and brand-new construction projects in 2020 In this guide we'll cover the following most typical roof options: asphalt shingles, wood shingles and shakes, metal roofing, concrete, clay, and fiber-cement tiles, natural and synthetic slate, and the much-hyped Tesla solar tiles that are not yet extensively offered.

Best Roofing Materials For Homes 2020: Material Costs, Plus

More than 75 percent of all single-family homes in the United States are roofed with asphalt shingles, though that number is slowly shrinking thanks to the more energy-efficient and long lasting metal roofing. Asphalt (structure) shingles dominate the marketplace since they are affordable, provide a variety of attractive options, and do a good job safeguarding houses from the nature's aspects.

:max_bytes(150000):strip_icc()/Roofers-Shingling-a-House-184332566-56a49bd23df78cf7728338d2.jpg) What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

Shingles made with fiberglass are light-weight and withstand tearing. Organic asphalt shingles begin with paper, typically recycled, that is saturated in asphalt and covered with granules. The shingles are much heavier and more difficult to work with than fiberglass, however they generally offer better stability in high winds. Although you can still see them on lots of roofing systems, natural shingles have actually been mostly phased out or stopped over the course of last decade.

https://www.youtube.com/embed/m2E7Nb0HGk4

Fiberglass shingles use great fire protection Look excellent on a lot of any style home Shingles are often the most economical roofing choice, especially in good/better varies The very best asphalt shingles are a 30-year roof solution set up on homes located in moderate climates The most inexpensive 3-tab shingles are a budget friendly method to dress up a home prior to selling Broad choice of colors and designs consisting of budget-friendly three-tab and architectural shingles that mimic shakes and slate DIY asphalt shingle setup is possible for those with great skills, experience and equipment No assistance beyond standard roof sheathing is needed for shingles are ranked for 60-70 Miles Per Hour wind uplift, while requirement are ranked for 110 MPH winds; are ranked for 130 Miles Per Hour such as the ones produced by GAF must be utilized for heavily-wooded places and areas where large hail is possible Some shingle repair work are simple and economical The life time expense of shingles is greater how much to fix the roof than metal, tile or slate, since composition shingles must be changed more regularly Cheaper asphalt shingles last as little as 10-15 years in hot, bright climates Fast temperature changes can trigger asphalt shingles to crack A badly vented attic will trap heat and significantly shorten asphalt shingle lifespan by cupping or cracking them While the asphalt shingle market boasts that its products can be recycled for paving, few recycling facilities take asphalt shingles, and they are among the least environment-friendly roofing alternatives After a 2nd layer of shingles needs replacing, all layers should be torn off the roofing, creating additional cost and a great deal of potential landfill waste Mold or algae can be a problem on shingles in shady locations, unless treated with anti-algae/anti-stain treatments Organic/felt shingles are heavy; getting them to the roof in bundles can be a challenge Wood provides a natural dose of beauty to any roofing.

What Roofing Material Is The Best?

Table of Contents15 Best Roofing Materials: Costs, Features And Benefits5 Reasons Why A Metal Roof Is The Perfect RoofHow To Choose The Right Roofing Material

March 21, 2019 by A strong roof is a fundamental part of any home, not only for the security it offers to the dwelling itself and to its residents, however due to the fact that it improves the house's curb appeal, and increases the value of the home. If your roofing is old and has started degrading, shingles might have started splitting or falling off, and it will probably establish leaks.

Although there are many kinds of roofing products, at this moment you might desire to get the one that lasts the longest so that you do not need to concern yourself with this problem again in the foreseeable future. Many roof products last a long time. Several years is a regular timespan for a good roofing system to last.

What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

To help you make a good choice, here is a list of a few of the most popular roof materials in use today and their life span: Metal Life-span goes from 40 to 80 years Slate Has a life span of 100 years Wood shingles These have a natural life of 30 years however can last longer in moderate weather conditions Wood shakes They work along with wood shingles and last the very same Architectural asphalt They provide security for about thirty years usually Concrete Must last about 100 years or more Asphalt shingles They usually last about 20 years, although higher quality shingles might go as long as 50 years (though higher quality shingles are certainly more pricey) Clay tiles These are rated for a life span of 100 years or more Among the main reasons roofing systems fail too soon is because of overlook.

The quality of the craftsmanship is likewise an important element to consider when choosing the ideal Portland roofing contractor to do the task. When all those components come together, the right roofing material will definitely meet or exceed its life span. Undoubtedly, the weather condition is accountable for a large how much to fix roof shingles part of what happens to a roof that may not be avoidable.

Nevertheless, you can take some preventative actions to guarantee no additional damage takes place: Watch of small locations of damage Call your roofer in Portland to take care of them prior to they end up being bigger Remove snow and ice when they collect Trim tree branches that may hit it during serious weather Install attic insulation to avoid ice dams Eliminate moss that shows up Keep your gutters tidy When the time comes for your roof to be fixed or replaced, call your trusted Portland roofer.

How Long Does A Roof Last - Updated Guide For 2020

The longest lasting roofings are normally made from products that decay extremely slowly, such as concrete, clay, and slate. Roofs made of metal are likewise extremely long enduring. Asphalt shingle and wood shingle roofing systems tend to have the fastest life-spans. When identifying the longest long lasting roof, one significant aspect is the quality of the roof product.

Numerous ancient structures boast clay or concrete roofs that are centuries old. Slate shingles, which are made of stone, are also extremely long lasting. Metal has also remained in use for roofing for centuries. Historically, copper was a typical metal for roof. It responds well to the elements and does not require any additional coating to keep it from rusting.

In addition to its long life expectancy and ease of usage, contractors have actually always used copper roof for its beauty, both in its raw and weathered states. Slate is a kind of stone that roof coating contractors is laid straight onto a roof. It is heavy and extremely durable. Slate is likewise invulnerable to insects and rot.

The Top 7 Most Durable, Long Lasting Roof Materials

The Top 7 Most Durable, Long Lasting Roof Materials

One thing to take think about when utilizing slate shingles is the weight of the material. Slate, being stone, is very heavy. Not every home can support a full slate roofing. Slate roofing might need extra trusses to support the weight of a stone roof. Nevertheless, when it concerns longevity, slate roofs have to do with as good as it gets, quickly lasting over 100 years.

You can find numerous cement structures constructed centuries or even millennia age still standing. Modern concrete tiles can be found in a large range of shapes, designs, and colors. They can simulate the look of numerous other roofing materials. Some can be made to look like slate. Other designs duplicate the appearance of conventional https://ricardoptto012.page.tl/Most-Durable-Roofing-Materials-Available-On-The-Market-Today.htm clay tiles.

What Is The Longest Lasting Roofing Material?

Some modern clay tiles are even produced to appear like natural materials such as wood shake or shingles. Concrete tiles have lots of advantages. They usually have an A fire score, meaning they are one of the most fire resistant. They also withstand damage from insects and animals. Nevertheless, there are some drawbacks.

A lot likewise depends upon how the cement roof is set up. Water from blowing rain or snow might be able to penetrate the areas between shingles. That can making the uderlayment particularly crucial. The tiles themselves are frequently offered a leak-proof covering. Clay tiles are another traditional roof product with a long history and excellent longevity.

It's use as a roof product goes back thousands of years, and numerous clay tile roofings are still standing centuries after they were installed. Modern clay tiles take a number of styles, from the standard to the contemporary. Both the Ancient Greeks and the Spanish missions used the barrel tile.

It is typically red and has a very traditional appearance. Its red color reflects the natural color of the terra-cotta material. Barrel tile is often chosen for its particular look in addition to its durability. Flat clay shingles offer a traditional European appearance. Like barrel tiles, numerous home builders choose these tiles for their distinct appearance.

https://www.youtube.com/embed/6BQrCxdvMR8

Lots of manufacturers also produce interlocking clay tiles, lowering the time and cost for installation. Copper roofings have been around for centuries, but contemporary steel roof is a reasonably recent development. Like modern-day cement and clay roofings, metal roof mimics a variety of other more conventional designs. Metal roof can refer to a number of different products.

Silicone And Acrylic Roof Coatings

Table of ContentsLiquid-applied RoofingLiquid Applied Roof SystemAll About Liquid Applied Silicone Membrane RoofingKm Coatings: Commercial Grade Liquid-applied Roof SystemsAdvancements In Fluid Applied Membranes For Roofing

Include membranes that are set up "in location" using extremely durable, water based, waterproofing compounds strengthened with difficult polyester materials and roof coating cost surfaced with energy saving reflective finishings. how much to repair a roof Once set up the smooth monolithic system is tough, flexible and resistant to the extremes of nature. We utilize Underwriters Laboratories (U.L.), FM Global and independent testing laboratories to continuously check our Systems and Products to be sure they fulfill the stringent requirements of today's structure market.

Western Colloid's Fluid Applied System's lead to a seamless finish making future assessments and maintenance easy. It likewise means the roofing can be resurfaced, thereby extending the life of the roofing system indefinitely. Western Colloid's FARR system's can be applied over BUR, Modified Bitumen, Single Ply, Metal Roofing, Sprayed Polyurethane Foam and Gravel roofings.

Save money on energy and equipment expenses (starting right away after the roofing is installed). Forever extend or eliminate your need to re-roof or handle major repair work. Can be applied over your existing roofing with really little trouble. Will not affect employee/tenant efficiency due to fumes. Can be shipped in bulk to the task website through our big fleet of tankers.

Fluid-applied Roof Coatings

Paints, Coatings, Liquid-applied Membranes: Understanding

Paints, Coatings, Liquid-applied Membranes: Understanding

No poisonous fumes or fire danger. Every product is backed by experience and efficiency. Much of our FARR systems have received UL Class A ratings. "Class A" roofing system assemblies have the greatest fire resistance. Furthermore, a number of our systems have likewise received FM 4470 Class 1 approval. To achieve this classification, the system goes through difficult screening for fire, hail damage, water leakage, and resistance to foot traffic.

Throughout the middle of the 19th century, modern-day roofing as we understand it began to take shape when rag felt taken in tar was layered with hot-mopped tar and covered with gravel. Gradually, the tar was mostly replace by asphalt and the rag felt by fiberglass mat to develop the modern-day built-up roofing system (BUR).

Product Evaluation

Product Evaluation

According to Jason Smith, senior R&D chemist at the Garland Company, cold-applied roof systems describe roofs that are adhered with an adhesive that doesn't require to be warmed prior to its application. They are utilized right out of the drum or pail and used using a notched squeegee, or also by brush, spray, or roller, depending upon the viscosity of the product.

Fluid-applied Roofing Contractor

Lee Martucci, product manager at GAF, notes, "The innovation was developed as a method to counter issues over potentially dangerous hot asphalt and fumes. When installing a roofing system without the big, messy hot kettles and fumes, the ecological and health issues from the pubic reduce. Plus, specialists can install the membrane systems without purchasing costly kettles: all they require is a squeegee." Cold-applied roof gets rid of untidy hot tar kettles and the associated fumes, which produces a much safer jobsite and less irritation for the building occupants.

George Daisey, a research scientist at Dow Chemical Company, explains that cold-applied roofing system setups enable for more secure handling of products, as there is no hot container to be hoisted onto the roofing system. Similarly, the application process gets rid of the potential for burns or breathing inflammation from hot fumes. Overall, cold-applied roofing system systems result in a lower level of odor at the job https://www.liveinternet.ru/users/nualla8qva/post475554370/ website, which Martucci suggests can result in fewer problems from constructing occupants.

With much less devices required than in a hot-applied roof job, the overall devices costs are significantly lower. Smith, at Garland, explains that cold-applied roofing systems can be formulated to have lower volatile organic substance (VOC) emissions, which can be of significance in VOC-restricted areas like California and much of the northeastern U.S.

Everything About Liquid Roofs

Paints, Coatings, Liquid-applied Membranes: Understanding

Paints, Coatings, Liquid-applied Membranes: Understanding

According to Daisey, the term "cold-applied roofing system" was initially utilized to describe a solvent-based built-up roofing system that did not require heat to install. Today, the term has actually expanded considerably as a variety of innovations have actually been established to include the range of roof systems that do not require heating to be installed.

Cold-Process Built-Up Roof uses heavyweight asphalt-impregnated fiberglass base sheets adhere in numerous plies with solvent-borne asphalt adhesives. The very first sheet is typically mechanically connected to the substrate (typically insulation) and subsequent plies (normally three or 4 overall) are embedded in an application of adhesive at a rate typically between 1.5 and 2.5 gallons per 100 sq.

Cold-process BUR utilizes solvent-based asphalt adhesives to adhere several layers of base sheet without heat. The membrane is then covered with aggregate. Once the waterproofing layer remains in location, the membrane is covered with an aggregate surface or roof coating. Modified Bitumen Roof is an adjustment of "torch-down" roof. Customized bitumen roofings were generally set up utilizing a gas torch to melt the back of the sheet, creating a molten adhesive in which the roll could be embedded.

Acrylic Coatings For Roofing

For obvious security reasons, usage of cold-applied roofing has provided an attractive alternative to making use of hot asphalt or open flame. These roofs typically have a mechanically connected base sheet, and a couple of plies of customized bitumen membrane installed in bituminous adhesives. Smith describes these adhesives as "rubber-modified fibered solvated asphalt adhesives that dry by means of solvent evaporation." Martucci adds, "These constructions usually consist of asphalt/solvent blends used by a squeegee to adhere the membranes to the substrate of other membranes, although there are other technologies that can be utilized.

Monolithic Liquid-Applied Roof blurs the line between roofing finish and roof membrane system. Usually made of high-tech polymeric resins such as urethanes, these roofing systems are applied as a liquid and often require no reinforcing product, curing to a tough, rubber-like membrane. (See sidebar below). Naturally, as is the case with all roof innovations, there are particular disadvantages to making use of cold-applied roofing systems.

https://www.youtube.com/embed/tarwNncXsNE

Liquid-Applied Roof is applied as a liquid and frequently requires no strengthening material, treating to a difficult, rubber-like membrane. Extra factors to consider include the flammability of cold-applied adhesives that are made with solvated asphalt, in addition to the capacity for solvent smell to penetrate through inhabited areas through vents, just as with the smells from hot-applied roofing systems.

Can You Walk On Elastomeric Roof Coating?

Table of ContentsSilicone Roofing MythsElastomeric Roof CoatingsHow Much Does Roof Coating Cost Per Square FootWhite Elastomeric Roof Coating

They need more product to accomplish the desired dry film density, making them less economical than other elastomeric coverings. They can also be challenging to spray and hard on application equipment. Silicone roofing finishings are the preferred choice when it concerns UV protection and resistance to ponding water. They deteriorate much slower than other coatings without ending up being breakable or hard.

This means less product is required to achieve the required dry film density. Silicone finishings are developed by including solvents and a driver to a silicone base. Offered in white, gray, or tan, how much to fix a roof silicone can be set up on a range of roofing system types including metal, modified bitumen, single-ply, EPDM, built-up roofing systems, and spray polyurethane foam.

Silicones attract dirt rather easily. This means the system will gradually lose reflectivity over time if not cleaned occasionally. They are also exceptionally slippery when wetness is present. Resistance to tearing is another inherent weakness. If pedestrian traffic is anticipated on the roofing, we extremely advise integrating roofing granules into the system.

When it pertains to strength, toughness, and adhesion, urethane roofing system finishings are 2nd to none. Compared to other finishes, they are more impact-resistant and are much better suited to manage pedestrian traffic. They are also strong enough to sustain the natural expansion and contraction (thermal motion) of roofing system structures and the unfavorable impacts of ponding water.

How Much Does It Cost To Coat Or Seal A Roof?

Aliphatics are normally utilized as top http://jaidenwnyq174.theburnward.com/elastomeric-roof-coatings coat, as they are more UV stable, resistant to dirt pick-up, and have remarkable color retention. Aromatics are less expensive however not rather as UV stable. They are primarily utilized as a foundation finish in a lot of roof restoration systems. Both types can be spray or roll-applied, with a lot of system specs needing several coats at a rate of 1.5 gallons per 100 square feet.

Elastomeric Roof Coating

Elastomeric Roof Coating

It's likewise worth discussing that urethanes are a moisture-cure finishing, indicating they are constantly curingeven in the pail. Every commercial roofing is various. That's why it's crucial to examine particular physical residential or commercial properties of a covering to guarantee its suitability in a particular roof environment. Each property listed below, along with other technical data, can be discovered in the producer's product information sheets.

A lot of elastomeric coverings typically measure anywhere between 250-900%. The higher the elongation value, the more suited a finishing is to withstand the normal growth and contraction of a roof structure without breaking, thinning, or removing. Tensile strength is the quantity of pressure a product can withstand before it breaks.

Elongation and tensile strength are carefully related but in an inverted direction. As one increases, the other decreases. The very best commercial roof finishing solutions balance the two homes to provide a strong, long lasting membrane that can properly extend and move with roof surface areas. Permeability, or perm score, is the state or quality of a product or membrane that triggers it to allow liquids or gases to go through it.

Quick Reference: Types Of Roof Coatings

Can You Walk On Elastomeric Roof Coating?

Can You Walk On Elastomeric Roof Coating?

For instance, acrylics have a high perm rating, indicating they are really breathable. Silicones, on the other hand, have a lower perm rating implying they have remarkable resistance to moisture transmission. It is very important to keep in mind that higher permeability does not correspond to inferior weather resistance. Reflectivity determines the amount in which a material can reflect light.

Unlike traditional, dark-colored roofing products, white roofing system finishing systems reflect 80-90% of the sun's energy back into the atmospheresignificantly decreasing the danger of heat gain throughout the roof structure. Emissivity describes a material's ability to launch absorbed heat. This home is normally represented as a decimal between 0 and 1, with 0.65 being thought about perfect for an elastomeric roofing coating.

Solids by volume is the measure of how much solid material will remain after a compound has actually dried. Understanding this home is important in order to correctly attain the required dry film thickness specified for certain finishing systems. While it has no bearing on the efficiency of a covering, this specific property is definitely worth some consideration.

For a complete introduction of the physical residential or commercial properties for American WeatherStar products, click on this link to download our complete roof finishing comparison chart. Ultimately, the performance of a business roof covering depends on a variety of elements. Each chemistry has its own distinct set of strengths and weaknesses. Things like roofing type, age, ecological concerns, visual appeals, and more must be considered prior to picking a suitable, long-term service.

Silicone And Acrylic Roof Coatings

In the commercial roofing worldand particularly in our restoration/revitalization specialty areawe use a lot of technical terms that we understand our consumers might not recognize with. This not surprisingly results in a lot of concerns, and it's our goal to educate the structure owners and managers we deal with as we bring new life to old, exhausted roofings.

What Is & How To Apply Elastomeric Roof Coating

What Is & How To Apply Elastomeric Roof Coating

While there tends to be some difference in the market regarding what particular roof finishes and products qualify as "elastomeric," the meaning of this term is quite easy. It describes substances that are elastomers, or that have elastic residential or commercial properties. Simply put, elastomeric materials stretch and can return to their initial measurements after doing sothink of an elastic band, and you'll have the ideal idea.

They are extremely protective against severe weather condition, UV light from the sun, and even foot traffic on your roofing system. The kind of elastomeric coating that's most suitable for your business structure's roofing system residential roofing specialists will depend on what products it was originally made from. Professional roofing specialists like us will work with you to assist you pick the best-performing finish for your unique roofing.

https://www.youtube.com/embed/prJIQ-5U_PU

Elastomeric roof finishes are developed to help stop leakages in aging roof systems made from a range of materials, like metal, layered asphalt, single-ply membranes, and more. When effectively applied by experts, these restorative finishings can seal bothersome joints and create a 100% leak-proof barrier throughout the surface area of your roofing.

Best Roofing Materials For Homes 2020: Material Costs, Plus

Table of ContentsRoofing Materials4 Best Flat Roof MaterialsWhich Roofing Material Lasts The Longest

March 21, 2019 by A strong roofing is a crucial part of any home, not only for the security it provides to the residence itself and to its occupants, but due to the fact that it improves the home's curb appeal, and increases the worth of the home. If your roof is old and has begun weakening, shingles may have begun breaking or falling off, and it will most likely develop leakages.

Although there are numerous kinds of roofing products, at this moment you may wish to get the one that lasts the longest so that you do not need to concern yourself with this issue once again in the foreseeable future. The majority of roof products last a long time. Several years is a typical amount of time for a great roofing system to last.

Different Types Of Roofing Materials Available

Different Types Of Roofing Materials Available

To help you make a great selection, here is a brief list of a few of the most popular roofing materials in usage today and their life span: Metal Life-span goes from 40 to 80 years Slate Has a life span of 100 years Wood shingles These have a natural life of thirty years however can last longer in moderate weather Wood shakes They work in addition to wood shingles and last the very same Architectural asphalt They offer security for about 30 years usually Concrete Must last about 100 years or more Asphalt shingles They usually last about 20 years, although greater quality shingles could go as long as 50 years (though greater quality shingles are definitely more expensive) Clay tiles These are rated for a life expectancy of 100 years or more One of the main reasons roofs stop working too soon is due to neglect.

The quality of the craftsmanship is likewise an essential aspect to think about when choosing the ideal Portland roofer to do the task. When all those components come together, the best roof material will certainly fulfill or exceed its life span. Undoubtedly, the weather condition is accountable for a large part of what happens to a roofing that might not be preventable.

However, you can take some preventative actions to guarantee no further damage occurs: Be https://diigo.com/0in9sm on the lookout of little areas of damage Call your roofer in Portland to take care of them before they end up being larger Eliminate snow and ice when they build up Cut down tree branches that might hit it during extreme weather Install attic insulation to prevent ice dams Get rid of moss that shows up Keep your gutters tidy When the time comes for your roofing to be repaired or changed, call your trusted Portland roofing contractors.

Different Types Of Roofs That Increase Home Value

The longest enduring roofing systems are normally made of materials that decay really roof replacement gradually, such as concrete, clay, and slate. Roofs made from metal are also very long enduring. Asphalt shingle and wood shingle roofings tend to have the fastest life expectancies. When identifying the longest long lasting roof, one significant factor is the quality of the roofing material.

Many ancient buildings boast clay or concrete roofing systems that are centuries old. Slate shingles, which are made of stone, are likewise very long lasting. Metal has also been in usage for roofing for centuries. Historically, copper was a typical metal for roof. It responds well to the elements and does not require any additional coating to keep it from rusting.

In addition to its long life-span and ease of usage, home builders have actually constantly utilized copper roof for its appeal, both in its raw and weathered states. Slate is a type of stone that is laid straight onto a roofing. It is heavy and exceptionally long lasting. Slate is also impervious to insects and rot.

What Is The Longest Lasting Roofing Material?

What Is The Longest Lasting Roofing Material?

One thing to take consider when using slate shingles is the weight of the product. Slate, being stone, is extremely heavy. Not every home can support a complete slate roof. Slate roofing may require extra trusses to support the weight of a stone roof. Nevertheless, when it pertains to durability, slate roofing systems are about as good as it gets, easily lasting over 100 years.

You can discover numerous cement structures constructed centuries and even millennia age still standing. Modern concrete tiles come in a variety of shapes, designs, and colors. They can simulate the look of lots of other roofing products. Some can be made to appear like slate. Other styles duplicate the appearance of traditional clay tiles.

Longest Lasting Roof Styles

Some contemporary clay tiles are even produced to look like organic products such as wood shake or shingles. Concrete tiles have many benefits. They usually have an A fire ranking, implying they are the many fire resistant. They also withstand damage from bugs and animals. Nevertheless, there are some disadvantages.

A lot likewise depends upon how the cement roofing is set up. Water from blowing rain or snow might be able to penetrate the areas between shingles. That can making the uderlayment especially essential. The tiles themselves are often provided a watertight finishing. Clay tiles are another traditional roofing material with a long history and great longevity.

It's use as a roof product goes back thousands of years, and many clay tile roofing systems are still standing centuries after they were installed. Modern clay tiles take a number of designs, from the conventional to the modern. Both the Ancient Greeks and the Spanish objectives utilized the barrel tile.

It is typically red and has a very conventional look. Its red color shows the natural color of the terra cotta material. Barrel tile is frequently chosen for its specific appearance in addition to its longevity. Flat clay shingles supply a traditional European appearance. Like barrel tiles, lots of contractors select these tiles for their distinct look.

https://www.youtube.com/embed/zbmWX4DvFfY

Many makers likewise produce interlocking clay tiles, reducing the time and expense for setup. Copper roofing systems have been around for centuries, but modern-day steel roof is a relatively licensed roofing contractors current development. Like modern-day cement and clay roofs, metal roofing mimics a number of other more standard designs. Metal roof can refer to a number of different materials.

Liquid Applied Roofing

Table of ContentsEverything About Liquid RoofsTypes Of Liquid Applied Roof Waterproofing SystemsRoof Problem Areas Addressed By Liquid Roofing MaterialsCold Liquid-applied RoofingLiquid Roofing - Answering Your Questions

Consist of membranes that are set up "in place" using extremely long lasting, water based, waterproofing compounds enhanced with difficult polyester materials and surfaced with energy conserving reflective finishings. Once installed the seamless monolithic system is hard, flexible and resistant to the extremes of nature. We use Underwriters Laboratories (U.L.), FM Worldwide and independent testing labs to continuously test our Systems and Products to be sure they meet the rigid requirements these days's building market.

Western Colloid's Fluid Applied System's lead to a seamless surface making future evaluations and upkeep easy. It likewise means the roofing can be resurfaced, therefore extending the life of the roofing forever. Western Colloid's FARR system's can be applied over BUR, Modified Bitumen, Single Ply, Metal Roof, Sprayed Polyurethane Foam and Gravel roofing systems.

Save money on energy and devices costs (starting right away after the roof is installed). Indefinitely extend or remove your need to re-roof or deal with major repair work. Can be used over your existing roof with really little trouble. Will not affect employee/tenant efficiency due to fumes. Can be shipped wholesale to the task website via our big fleet of tankers.

Liquid Applied Roofing Products

No toxic fumes or fire risk. Every product is backed by experience and efficiency. A number of our FARR systems have actually gotten UL Class A ratings. "Class A" roofing system assemblies have the best fire resistance. Furthermore, much of our systems have actually also gotten FM 4470 Class 1 approval. To achieve this designation, the system undergoes laborious screening for fire, hail damage, water leakage, and resistance to foot traffic.

Throughout the middle of the 19th century, contemporary roof as we understand it started to take shape when rag felt soaked in tar was layered with hot-mopped tar and covered with gravel. In time, the tar was mostly change by asphalt and the rag felt by fiberglass mat to produce the modern-day built-up roofing system (BUR).

Fluid-applied Roofing Systems Brochure

Fluid-applied Roofing Systems Brochure

According to Jason Smith, senior R&D chemist at the Garland Business, cold-applied roof systems refer to roofing systems that are adhered with an adhesive that doesn't require to be warmed prior to its application. They are utilized best out of the drum or pail and used utilizing a notched squeegee, or also by brush, spray, or roller, depending upon the viscosity of the product.

Liquid-applied Waterproofing Roofing Products

Lee Martucci, product supervisor at GAF, keeps in mind, "The innovation was developed as a method to counter concerns over possibly hazardous hot asphalt and fumes. When installing a roofing without the big, unpleasant hot kettles and fumes, the environmental and health issues from the pubic minimize. Plus, professionals can install the membrane systems without purchasing pricey kettles: all they require is a squeegee." Cold-applied roofing eliminates unpleasant hot tar kettles and the associated fumes, which develops a safer jobsite and less irritation for the building residents.

George Daisey, a research researcher at Dow Chemical Company, points out that cold-applied roof setups enable more secure handling of materials, as there is no hot container to be hoisted onto the roof. Likewise, the application process removes the potential for burns or respiratory inflammation from hot fumes. Overall, cold-applied roofing systems result in a lower level of odor at the job website, which Martucci suggests can lead to less grievances from building occupants.

With much less equipment needed than in a hot-applied roof job, the general equipment costs are significantly lower. Smith, at Garland, explains that cold-applied roofing system systems can be created to have lower volatile natural compound (VOC) emissions, which can be of significance in VOC-restricted areas like California and much of the northeastern U.S.

Paints, Coatings, Liquid-applied Membranes In Roofing

Liquid Applied Roofing Solutions

Liquid Applied Roofing Solutions

According to Daisey, the term "cold-applied roof system" was originally utilized to describe a solvent-based built-up roofing system that did not need heat to install. Today, the term has actually expanded considerably as a range of innovations have actually been developed to encompass the range of roof that do not need heating to be installed.

Cold-Process Built-Up Roofing uses heavyweight asphalt-impregnated fiberglass base how much does it cost to repair roof leak sheets adhere in multiple plies with solvent-borne asphalt adhesives. The very first sheet is usually mechanically connected to the substrate (typically insulation) and subsequent plies (normally 3 or four total) are embedded in an application of adhesive at a rate typically between 1.5 and 2.5 gallons per 100 sq.

Cold-process BUR uses solvent-based asphalt adhesives to adhere numerous layers of base sheet without heat. The membrane is then covered with aggregate. As soon as the waterproofing layer remains in location, the membrane is covered with an aggregate surface area or roof finishing. Modified Bitumen Roof is an adaptation of "torch-down" roofing. Customized bitumen roofs were traditionally set up utilizing a gas torch to melt the back of the sheet, developing a molten adhesive in which the roll might be embedded.

Liquid Applied Rubber Roofing Systems

For obvious security reasons, https://blogfreely.net/agnathaeo0/b-table-of-contents-b-a use of cold-applied roof has provided an attractive alternative to making use of hot asphalt or open flame. These roofing systems generally have a mechanically connected base sheet, and one or two plies of modified bitumen membrane installed in bituminous adhesives. Smith explains these adhesives as "rubber-modified how much to fix shingles on roof fibered solvated asphalt adhesives that dry via solvent evaporation." Martucci includes, "These buildings usually include asphalt/solvent blends used by a squeegee to adhere the membranes to the substrate of other membranes, although there are other technologies that can be used.

Monolithic Liquid-Applied Roof blurs the line between roofing system covering and roofing system membrane system. Normally made from state-of-the-art polymeric resins such as urethanes, these roofing systems are used as a liquid and typically require no strengthening material, treating to a hard, rubber-like membrane. (See sidebar listed below). Naturally, as is the case with all roof innovations, there are specific downsides to utilizing cold-applied roofing system systems.

https://www.youtube.com/embed/MrQEQcrjwFI

Liquid-Applied Roofing is used as a liquid and often needs no enhancing product, curing to a difficult, rubber-like membrane. Extra considerations consist of the flammability of cold-applied adhesives that are made with solvated asphalt, in addition to the potential for solvent odor to penetrate through occupied spaces via vents, just as with the smells from hot-applied roofing systems.

How Long Does A Roof Last - Updated Guide For 2020

Table of Contents18 Types Of Roof ShinglesDifferent Types Of Roofing Materials AvailableMost Durable Roofing Materials Available On The Market Today

It's not everything about the beauty, after all. It is also unequalled in the durability https://zenwriting.net/midingvk0u/b-table-of-contents-b-a department. Now that you have actually found the most lasting roof materials, let now speak about things that can assist them reach their max potential. Durability can vary. This is since of the several factors that impact roofing products' ability to lengthen their life service.

There are roof products that are shown to carry out well even in the middle of the harshest weather. To understand whether a roof product is high-quality or not, you need professional viewpoints from trusted roof specialists. Depending upon where you are located, there are roof that can flourish better in particular climates or weather.

Which Roofing Materials Last The Longest?

Which Roofing Materials Last The Longest?